What Makes Recycled Plastic Wood More Durable Than Wood?

One of the primary benefits of plastic wood over regular wood is that it’s more durable and will last longer. But what makes recycled plastic wood more durable than typical wood?

We’ll answer that question in our handy guide, where we go through the process of turning recycled plastic into lumber and outline how recycled lumber is more durable than standard wood.

How Recycled Plastic Wood Is Made

Before we get into the qualities and characteristics of plastic wood, it’s beneficial to understand the process of creating plastic wood from recyclables. By learning the recycled wood production process, we can better understand the significant differences between organic and synthetic materials.

From Your Curb To the Facility

Your recycled plastic has to go somewhere—and it could end up as part of the recycled plastics that manufacturers transform into plastic lumber. We all know to take out our recycling and see the recycling truck pick it up, but where does it go after that?

After picking up your recyclables, the recycling truck will go to a material recovery facility, which will then sort and organize the recyclables by material (paper, plastic, glass) and weight. After sorting the plastics, the facility will compress the raw plastic into bales, typically around 1,000-1,5000 pounds—which they then sell to manufacturers like us, Tangent Materials, that turn the plastic bales into something new.

Preparing the Plastic

Once the bales arrive at the manufacturing facility, it’s time to prepare plastic for its upcoming transformation. First, the facility washes the plastic and grinds it down into much smaller, manageable pieces that are easier to melt.

With the smaller pieces, plastic lumber manufacturers typically clean them again to remove any residue before they’re heated in an oven until melted. Once melted, the plastic is pushed through a cutter that turns it into tiny pellets.

The Final Mixture and Product

The plastic pellets are now ready to be mixed and combined with other materials to produce the synthetic material for plastic lumber. The manufacturer will blend the pellets with synthetic materials that modify the plastic’s strength, versatility, and color.

These additives create a more durable and strong plastic that helps it hold up against external conditions like moisture, wind, and UV rays. The final product is recycled plastic wood that can be morphed into any shape or dimension needed and can last for decades.

Why Plastic Lumber Is More Durable Than Wood

Now we know how it’s made, but what makes recycled plastic wood more durable than wood? What characteristics and qualities does it possess that distinguish it from typical lumber?

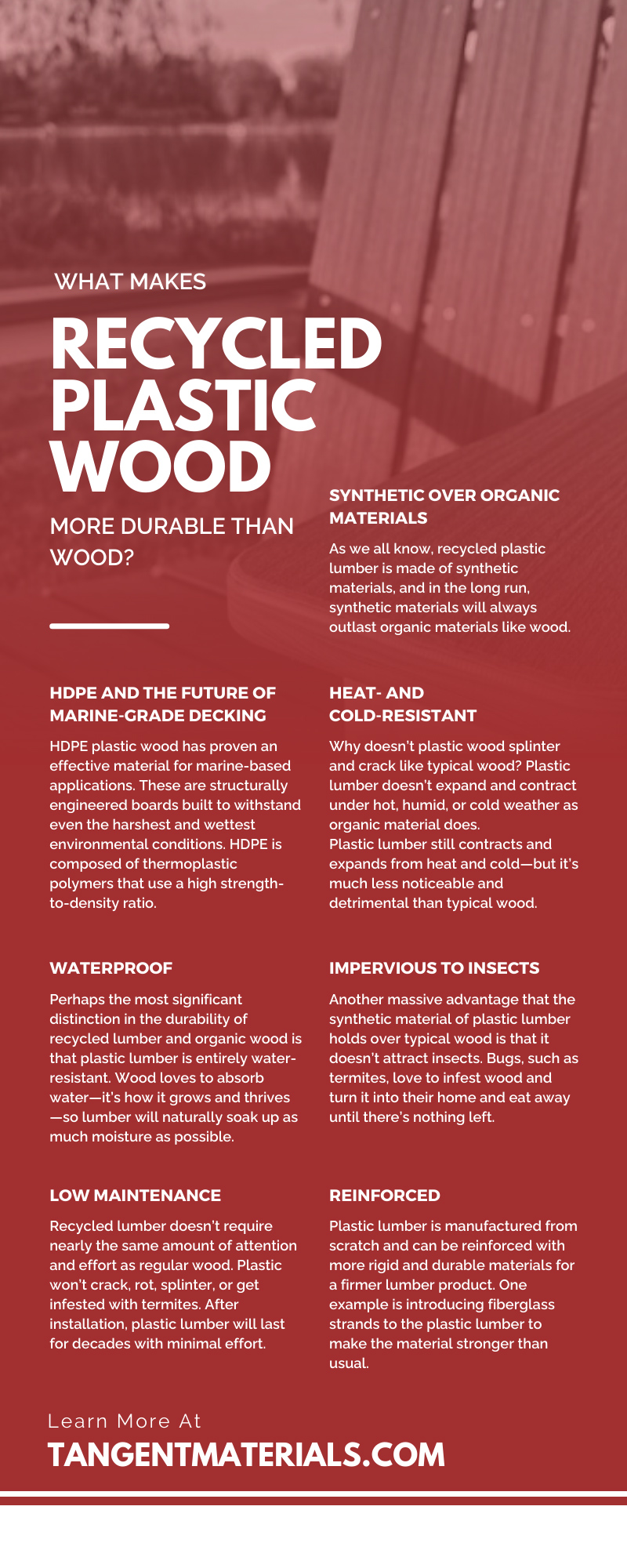

Synthetic Over Organic Materials

As we all know, recycled plastic lumber is made of synthetic materials, and in the long run, synthetic materials will always outlast organic materials like wood. As we outlined, recycled plastic goes through an arduous process that turns milk jugs and plastic trash into a rigid, durable material through heat and a mixture of other synthetic materials.

Due to its chemical makeup, plastic wood has a tougher and more impenetrable outer shell that doesn’t deteriorate or decay over time like wood. Even after years of punishment from the elements and use, plastic lumber won’t chip, rot, or splinter like organic wood.

Heat- and Cold-Resistant

Why doesn’t plastic wood splinter and crack like typical wood? Plastic lumber doesn’t expand and contract under hot, humid, or cold weather as organic material does.

Plastic lumber still contracts and expands from heat and cold—but it’s much less noticeable and detrimental than typical wood. The rigid, synthetic materials of recycled wood don’t absorb moisture like organic lumber, which means fewer and less intense fluctuations.

Waterproof

Perhaps the most significant distinction in the durability of recycled lumber and organic wood is that plastic lumber is entirely water-resistant. Wood loves to absorb water—it’s how it grows and thrives—so lumber will naturally soak up as much moisture as possible.

Moisture in lumber, however, leads to mold and rot, which are severe problems for wood decks and structures. Lumber requires paint, sealants, and stains to keep moisture out, but plastic lumber is waterproof. With no moisture infiltrating the plastic lumber, there’s no worry about rot or mold taking hold and wreaking havoc.

Impervious to Insects

Another massive advantage that the synthetic material of plastic lumber holds over typical wood is that it doesn’t attract insects. Bugs, such as termites, love to infest wood and turn it into their home and eat away until there’s nothing left.

Insect infestation in the lumber can destroy a wood structure, which is why they require diligent maintenance and preventative measures. But bugs have no interest in consuming and burrowing into plastic lumber—and the outer shell is so tough that they couldn’t burrow in if they wanted.

Low Maintenance

As we’ve mentioned throughout, organic wood requires a lot of maintenance to maintain its structural integrity and appearance. Water, bugs, UV rays, and more can wear away and destroy lumber after so many years—so wood requires regular maintenance.

Recycled lumber doesn’t require nearly the same amount of attention and effort. Plastic won’t crack, rot, splinter, or get infested with termites. After installation, plastic lumber will last for decades with minimal effort.

Reinforced

When it comes to wood, there’s not much one can do to improve its structural strength. Some woods are more rigid, but we can’t modify the lumber to strengthen its integrity.

Plastic lumber, on the other hand, is manufactured from scratch and can be reinforced with more rigid and durable materials for a firmer lumber product. One example is introducing fiberglass strands to the plastic lumber to make the material stronger than usual.

How Long Can Plastic Lumber Last?

We’ve discussed how recycled wood is more durable, but what does it all add up to? Whether you’re buying lumber or a toaster, you want your purchase to have value by lasting long—so how long does plastic lumber last.

Many variables determine the lifespan of plastic lumber, but almost all forms of recycled wood can last for decades. At Tangent Materials, we offer a 50-year limited warranty for our plastic lumber! Organic wood, however, is lucky to last up to 15 years, and that requires rigorous maintenance and care to make it survive that long.