The Ultimate Guide to Plastic Lumber for Construction

Innovation in construction is important as society continues to expand and require stronger, more sustainable options for expanding infrastructure.

In the last few decades, the accumulation of plastic has created opportunities for companies like Tangent Materials to rise to the challenge of creating something new out of old recycled milk jugs, laundry detergent bottles, and other landfill staples. Recycled plastic lumber is the long-lasting and durable solution to build sustainably in the future.

Are you looking to utilize plastic lumber in your next construction project? Stay on top of new advances in plastics and construction with our helpful guide to plastic lumber for construction.

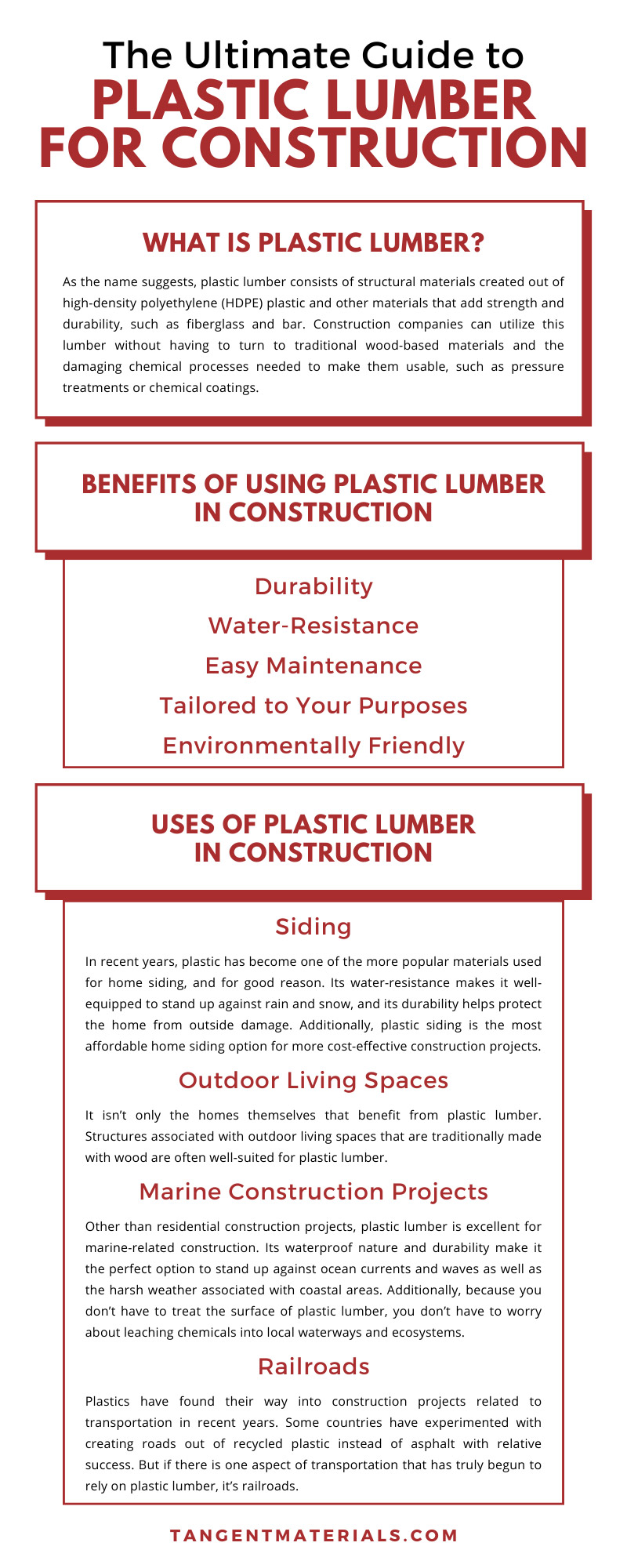

What is Plastic Lumber?

As the name suggests, plastic lumber consists of structural materials created out of high-density polyethylene (HDPE) plastic and other materials that add strength and durability, such as fiberglass and bar. Construction companies can utilize this lumber without having to turn to traditional wood-based materials and the damaging chemical processes needed to make them usable, such as pressure treatments or chemical coatings.

Benefits of Using Plastic Lumber in Construction

Durability

Wood has long been one of the most obvious choices for building materials. Along with being readily available, it’s a sturdy, natural material that is still simple to work with. Traditionally, lumber refers to wood boards, but alternative materials are becoming popular as people become more eco-conscious.

Plastic lumber is significantly stronger than wood and has something called flexural strength, which allows it to be run into without cracking or breaking. Plus, because it isn’t made of organic material, plastic lumber won’t splinter or chip like natural wood.

Water-Resistance

Most traditional building materials are far from water-resistant. Wood is prone to rotting and getting moldy when introduced to water, and chemical processes that make wood more water-resistant can leach into our waterways and damage ecosystems.

Even materials that can withstand moisture, like concrete and stone, are not completely immune to the ravages of water damage without waterproofing. Plastic lumber is completely waterproof without any extra treatment and resistant to moisture damage.

Easy Maintenance

As mentioned, plastic lumber does not require chemical treatment to make it resistant to water damage. Plastic surfaces wash off easily and won’t become breeding grounds for mold. Simply hosing the surface down is typically enough to remove most residue.

Tailored to Your Purposes

Finding the right material for your construction project is one thing—finding the material shaped to your specifications is another. Much of a construction project is often spent cutting down wood or shaping stone for the project. But when you order plastic lumber, you can typically have it engineered to your specifications and sent to you ready for use.

Environmentally Friendly

To call plastic environmentally friendly can seem far-fetched to some, but plastic lumber from Tangent Materials is made from recycled materials—reducing landfills and ocean-bound waste. Using plastic lumber also fights deforestation and reduces the number of trees that need to be felled for lumber each year. Because plastic is waterproof, it doesn’t need to be treated with chemicals, preventing water and soil pollution when used outside and in marine applications.

Uses of Plastic Lumber in Construction

Siding

In recent years, plastic has become one of the more popular materials used for home siding, and for good reason. Its water-resistance makes it well-equipped to stand up against rain and snow, and its durability helps protect the home from outside damage. Additionally, plastic siding is the most affordable home siding option for more cost-effective construction projects.

Outdoor Living Spaces

It isn’t only the homes themselves that benefit from plastic lumber. Structures associated with outdoor living spaces that are traditionally made with wood are often well-suited for plastic lumber. Some such structures include:

- Decks

- Wooden walkways

- Pergolas

- Gazebos

- Outbuildings

- Fencing

- Outdoor furniture

Along with being weather-resistant and easy to clean, plastic lumber works well for outdoor purposes. Coming in a variety of colors and woodgrain styles, plastic lumber can be selected to fit any décor style. Plastic lumber also tends to maintain its color well despite outside conditions.

Marine Construction Projects

Other than residential construction projects, plastic lumber is excellent for marine-related construction. Its waterproof nature and durability make it the perfect option to stand up against ocean currents and waves as well as the harsh weather associated with coastal areas. Additionally, because you don’t have to treat the surface of plastic lumber, you don’t have to worry about leaching chemicals into local waterways and ecosystems.

Common marine construction projects that construction experts turn to plastic lumber for are:

- Marine piling

- Docks

- Piers

- Boardwalks

- Bridges

Railroads

Plastics have found their way into construction projects related to transportation in recent years. Some countries have experimented with creating roads out of recycled plastic instead of asphalt with relative success. But if there is one aspect of transportation that has truly begun to rely on plastic lumber, it’s railroads.

Traditionally, railroad ties—the pieces of lumber that lie horizontally between the two metal rails—were made of wood. However, wood wears out over time and is subject to splintering and rot. Plastic lumber can withstand the rigors of passing trains without wearing down.

ASTM International Standards for Plastic Lumber

Most aspects of construction are subject to the standards developed by ASTM International, and plastic lumber is no exception. As such, any guide to plastic lumber in construction is incomplete without a brief overview of these standards. ASTM’s standards cover various attributes of plastic lumber, including:

- Flammability

- Board length limits for application

- Plastic lumber grade for application

- Flexural property testing

More in-depth information about the specifications of these standards can be found on ASTM International’s website.

The Future of Plastic Lumber for Construction

Plastic lumber has already revolutionized many construction projects, but its full potential has yet to be explored. As construction companies continue testing these materials’ limits, it’s possible that more elaborate structures will begin to feature plastic lumber.

ASTM, for instance, has approved plastic lumber for use in framing homes. This can be especially valuable in homes found in flood-prone areas, such as those built in Hurricane Alley. These homes would be less prone to mold and rot damage after flooding, saving affected homeowners a great deal of money.

If you’re ready to join the countless construction companies utilizing plastic lumber, visit Tangent Materials today. Our collection of structural plastic lumber comes in a variety of colors and grades, making it perfect for any project.