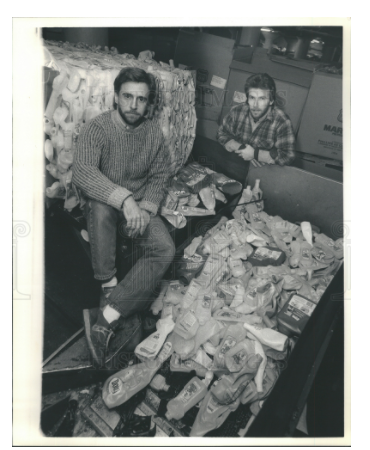

In 1983, Andy Stephens (Tangent Board of Directors) was a pioneer in the industry with the founding of Eaglebrook Plastics which was the first company in the United States to successfully recycle post-consumer recycled HDPE bottles back into recycled resin for reuse. Five years later in 1988, Eaglebrook Products was started with the mission to make recycled HDPE plastic lumber products from post-consumer recycled plastics. In the early 1990’s, Guy DeFeo (Tangent CEO) joined Andy Stephens at Eaglebrook Products along with Francisco Morales (Tangent Chief Innovation Officer) and the three of them hit it off, working hard and imagining how to turn recycled plastics into a multitude of possibilities for plastic lumber. In 1999, both Eaglebrook companies were sold to a public company. Eventually, four years later in 2003 the three of them decided to take their invaluable experience and start again by forming Tangent Technologies with the mission to be the most innovative plastic lumber company on the planet.

A history of innovation

Long before Tangent opened its doors in 2003, our founders were leading the way in the plastic lumber business.

A Tradition of Being Untraditional

When we first opened our doors in 2003, the majority of the industry was manufacturing products for decking. Our founders, Guy DeFeo (CEO), Francisco Morales (Chief Innovation Officer), and Andy Stephens (Board of Directors), saw an underserviced segment in the marketplace. With focus and innovation on plastic lumber for outdoor furniture and other applications, Tangent quickly grew from a 20,000 square-foot facility with four production lines to a 600,000 square-foot facility with 40 production lines and over 500 employees.

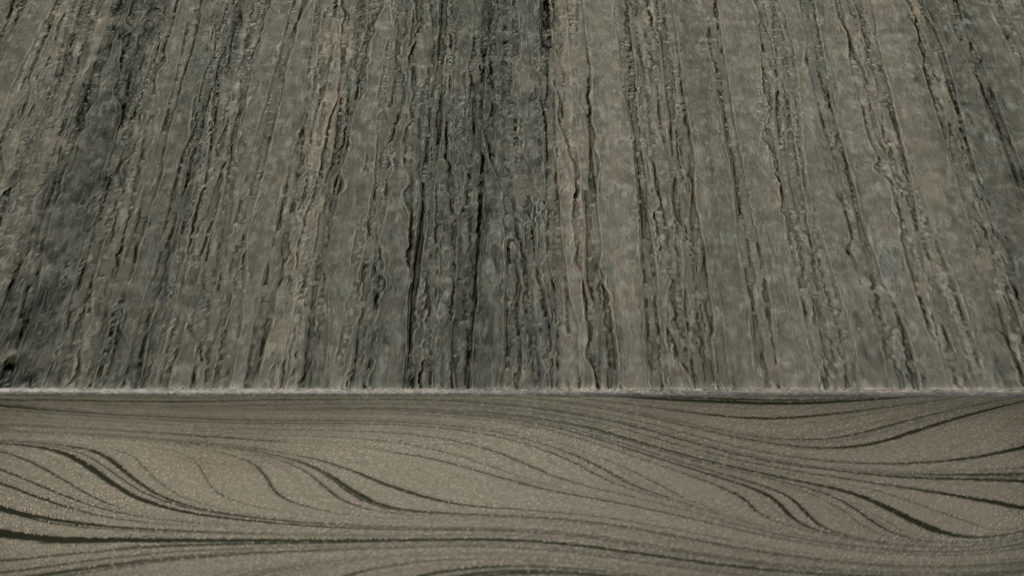

True to form, innovation never slowed. In 2016, we developed our patented woodgrain dimensional lumber, plastic lumber with an internal grain that looks like real hardwood. The product was revolutionary, opening new doors for the plastic furniture industry.

Today, Tangent manufactures hundreds of sizes of extrusions, many created around specific applications for customers. And by recycling 15,000 tons of plastic waste annually, including the equivalent of 210 million milk jugs, we strive to make products that are as environmentally friendly as they are durable. With continuous innovation and guaranteed performance, Tangent remains the category leader to this day.

Read more below:

Cool Timeline

With Tangent’s wide variety of sizes, colors, and product lines, you’re sure to find the right material for your job.