King County South Park Bridge Reconstruction Project Case Study

The King County South Park Bridge was originally built in 1931, spanned the Duwamish Waterway and was the first and only type of bridge built in the state of Washington. It remained an essential transportation link for almost 80 years, until King County was forced to close the bridge in 2010 due to dangerous and unsafe conditions. A new solution was needed to ensure that the bridge was safe and sustainable, and recycled plastic lumber played a huge role in making this happen.

Project Date:

2014

Customer Overview:

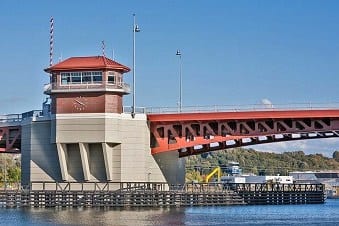

King County spans over 2,000 miles, includes the major metropolitan area of Seattle, and has the largest person per square mile ratio in the state. It is the largest metropolitan county in the Washington state pertaining to population, employment and the number of cities, and is the 13th most populated county in the United States. Along with dense population, King County owns and operates 182 bridges in the area. One of the bridges includes the South Park Bridge. The Bridge is a historic landmark drawbridge that spans over 1,200 ft. and serves as a link to the Duwamish Waterway.

Challenge:

An earthquake that occurred in 2001 caused major damage to the bridge, and as a result, the concrete was failing and the piles were not properly sunk into the solid footings when it was first constructed. The Federal Highway Administration gave the bridge one of the worst safety ratings in the state, and it was forced to close on June 30, 2010. The closing not only impacted the 20,000 vehicles that traveled the bridge on a daily basis and the numerous vessels and barges that passed through, but it also caused a huge uproar from the community, emphasizing the city’s neglect. As a result of that outrage and being a major transportation thoroughfare, the reconstruction of the bridge became a top priority for the county.

Solution:

One element of the bridge reconstruction was the bridge pier protection system, which includes over 350 wooden piles. Since the bridge was closed due to safety hazards, structural integrity and longevity were two main concerns. The King County engineers looked to SeaTimber® by Tangent to reconstruct the bridge pier fendering system. This product was attractive to engineers because it is manufactured in the United States and is made of recycled plastic.

Based on research and previous success, SeaTimber® by Tangent was the preferred product because of its structural integrity and ability to absorb energy and deflect barges and vessels bumping and scraping against the bridge. These piles allow the bridge protections system to absorb the energy from impact and not damage the actual structure.

SeaTimber® by Tangent also met the specifications for this project: the material needed within certain sizes (8×12 – 12×12), and meet the strength and stiffness requirements. Given that SeaTimber® will not rot, corrode, decay and is impervious to marine borers, the life-cycle cost is unbeatable.

Results:

In 2015, the South Park Bridge project received numerous awards including the 2015 Excellence in Structural Engineering Award from the National Council of Structural Engineers Association (NSCEA) and the #1 Project in the list of the 2015 Roads and Bridges Top Ten Bridges. These accolades only partly describe the results of this reconstruction project. The SeaTimber® by Tangent bridge protection system is has successfully guided over 700 boats, barges and vessels in 2017 alone and serves as an integral part of the new construction project for King County.

Greenroads. Old South Park Bridge. King County, Washington.

HNTB. Seattle, Washington.