Industrial Plastics: The Fall of Wood, Metal & Concrete

For many years, engineers have relied on wood, metal, and concrete to build various structures but now are turning to industrials plastics. Forest preserves used timber for walkways and park districts often purchased metal seating. Manufacturers also used wood for cribbing purposes.

But the old adage “All good things must come to an end” remains true in the industrial sector, too. Engineers formulated a new product that is friendlier to the planet, more durable to use, and more affordable than timber, metal, and concrete: recycled plastic lumber. Read on to find out more about industrial plastics and the fall of wood, metal, and concrete.

The Rise of Wood, Metal, and Concrete

Wood, metal, and concrete have been construction staples for centuries. Engineers required these materials to build everything from ships to skyscrapers, agricultural fencing, roadways, and commercial furniture. There were many critical benefits to each of these materials contributing to their rise:

Advantages of Metal (Steel)

Steel is made from mostly iron and carbon. Manufacturers can add additional elements to the mixture of iron and carbon to create new forms, such as stainless steel. In addition to the ability to customize and change the original steel’s form, the advantages of steel include:

- Strength. Steel has an impressive strength-to-weight ratio, making it ideal for high-rise buildings and bridges.

- Reliable properties. Due to its well-known and relatively unchanging properties, engineers and end-users alike can rely on steel to perform as it should for a considerable amount of time.

- Ease of installation. Steel is formed into beams, which are then quickly installed.

- Ease of repair. Steel can be repaired quickly and easily.

- Ease of expansion. Steel structures can easily be expanded or widened.

Advantages of Concrete

Concrete is made from a mixture of water, cement, and construction aggregates (sand, gravel, crushed stone, and recycled concrete, to name a few). Concrete can be mixed with varying ratios of each ingredient to achieve a certain strength. Once mixed, concrete must be poured immediately as it will begin to dry and harden. Some of the benefits of concrete in construction projects include:

- Strength. Concrete has an impressive compressive and tensile strength, making it ideal for a myriad of construction projects.

- Fire-resistant. Concrete resists fire and can protect structural steel from flames for long periods of time.

- Locally sourced. As aggregates are mined from virtually everywhere, concrete tends to be made from local materials.

- Endless options. Concrete can be molded into limitless shapes and applications.

- Low maintenance. Once poured, set, and hardened, concrete requires minimal maintenance.

Advantages of Wood

Timber is a natural material that can be found in many places all over the globe. Versatile in function, timber can be used to build a house, a ship, a floor, or a chair. Wood is also considered environmentally friendly in the fact that it disintegrates when exposed to the elements and can be easily reclaimed by nature.

- Lightweight yet incredibly strong. Timber is a relatively lightweight material yet can support its own weight incredibly well.

- Does not conduct electricity. When dried to standard moisture content levels, wood resists electrical conduction naturally.

- Dampens sound. The acoustic properties of wood do a phenomenal job absorbing sound.

- Eco-friendly. Wood breaks down quickly when exposed to the elements.

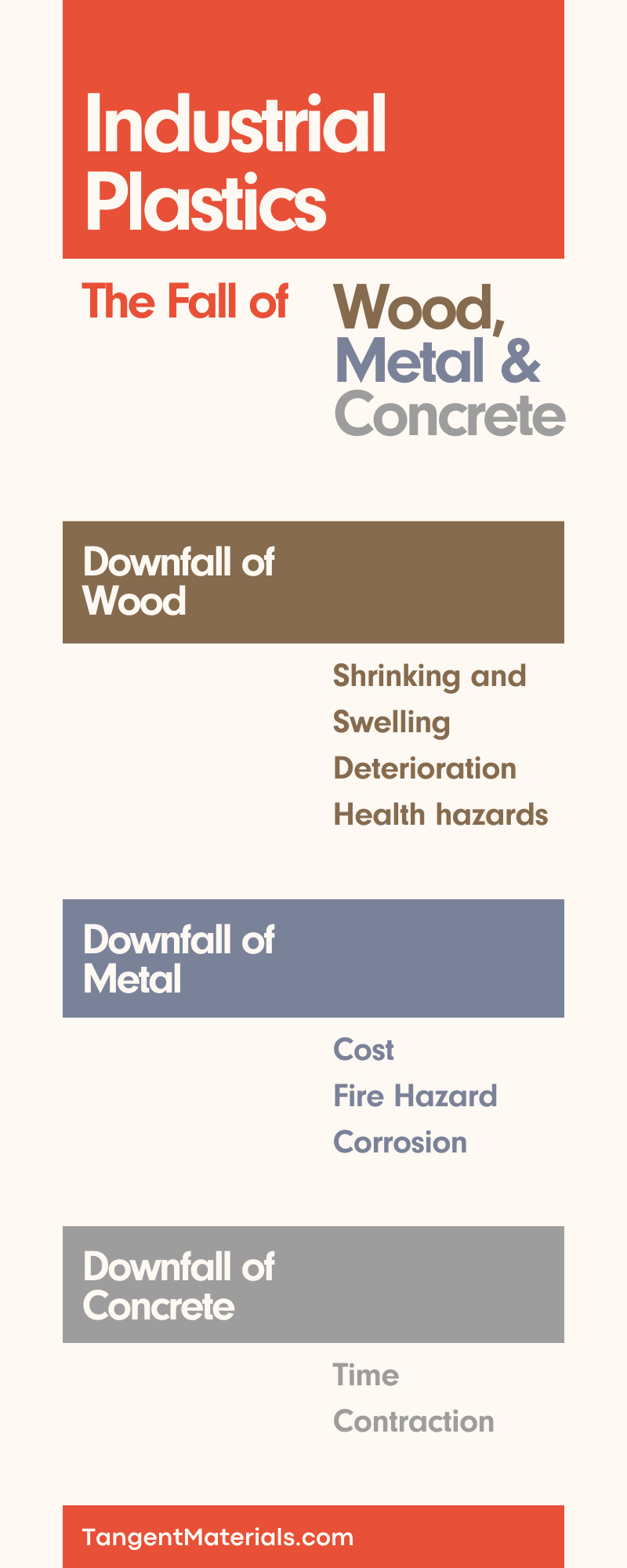

The Fall of Wood, Metal, and Concrete

With more and more people turning their focus to helping the planet and preserving our natural resources, many are turning away from wood in an array of construction projects and adapting to using industrial plastics. Clients with a tighter budget bypass the option of building with steel due to its costly production, transportation, and installation fees. And while concrete is a durable and low-maintenance material, there are other options on the market – such as plastic lumber – that better fit the bill (and the project).

There are a number of disadvantages to metal, concrete, and timber, including:

Downfall of Metal (Steel)

- Cost. Metals such as steel are expensive to produce due to the intensive and dangerous working conditions required to make it. Thus, steel structures tend to be more expensive than buildings built without steel.

- Fire Hazard. Steel is weakened dramatically when exposed to excessive temperatures, such as those produced by a fire. Steel is also excellent at conducting and transmitting heat. These factors alone make steel a less viable option for many buildings.

- Corrosion. Exposure to the elements can cause steel to corrode and collapse. Any exposed steel must be painted on a regular basis to prevent contact with water, air, and salt.

Downfall of Concrete

- Time. Concrete has an extensive curing time (approximately 30 days). During a construction project, the goal is to move quickly – especially when faced with tight deadlines, changing seasons, and impending weather threats. Additionally, concrete cannot be stored for any amount of time after it has been mixed. If storage is required, all ingredients must be stored separately.

- Contraction. Due to temperature changes, concrete tends to shrink. This can cause cracks and result in overall weakening.

Downfall of Timber

- Shrinking and Swelling. Fluctuating moisture levels, temperatures, and other natural conditions cause timber to shrink and swell. With enough passage of time, timber can lose its structural integrity.

- Deterioration. Exposure to sun, rain, snow, ice, salt, fog, mist, and insects cause significant damage. Wood absorbs moisture and begins to rot, can be eaten away by insects, and can be petrified by the sun.

- Health hazards. Due to wood’s tendency to absorb moisture, mold and other fungi love to make timber their home. This can cause health hazards for humans and animals alike.

The Emergence of Recycled Plastic Lumber and Other Industrial Plastics

When recycled plastic lumber emerged on the market as a building material, many contractors and engineers dropped steel, concrete, and timber in pursuit of this new product. Plastic is used in an array of applications, including plastic cribbing and plastic lumber. There is a myriad of benefits associated with industrial plastics and plastic timber that alleviate concerns caused by other materials. Some of the benefits include:

- Durable, economical, and eco-friendly alternative to wooden pathways.

- Resistant to pests and conditions such as weather, mildew, rot, fungi, and insects.

- Manufactured to closely resemble natural woods.

- Easy to install.

With the creation of recycled plastic lumber, many industries are reaping the benefits from the rise of industrial plastics and are seeing the fall of wood, metal, and concrete.