How Plastic Lumber Decking Is Redefining Normal Wear & Tear

Plastic lumber decking has many benefits and advantages over organic wood materials, but perhaps the most significant difference is how it holds up against normal wear and tear. In our guide, we’ll break down the vital elements of plastic lumber decking, from its history to its durability, benefits, and more.

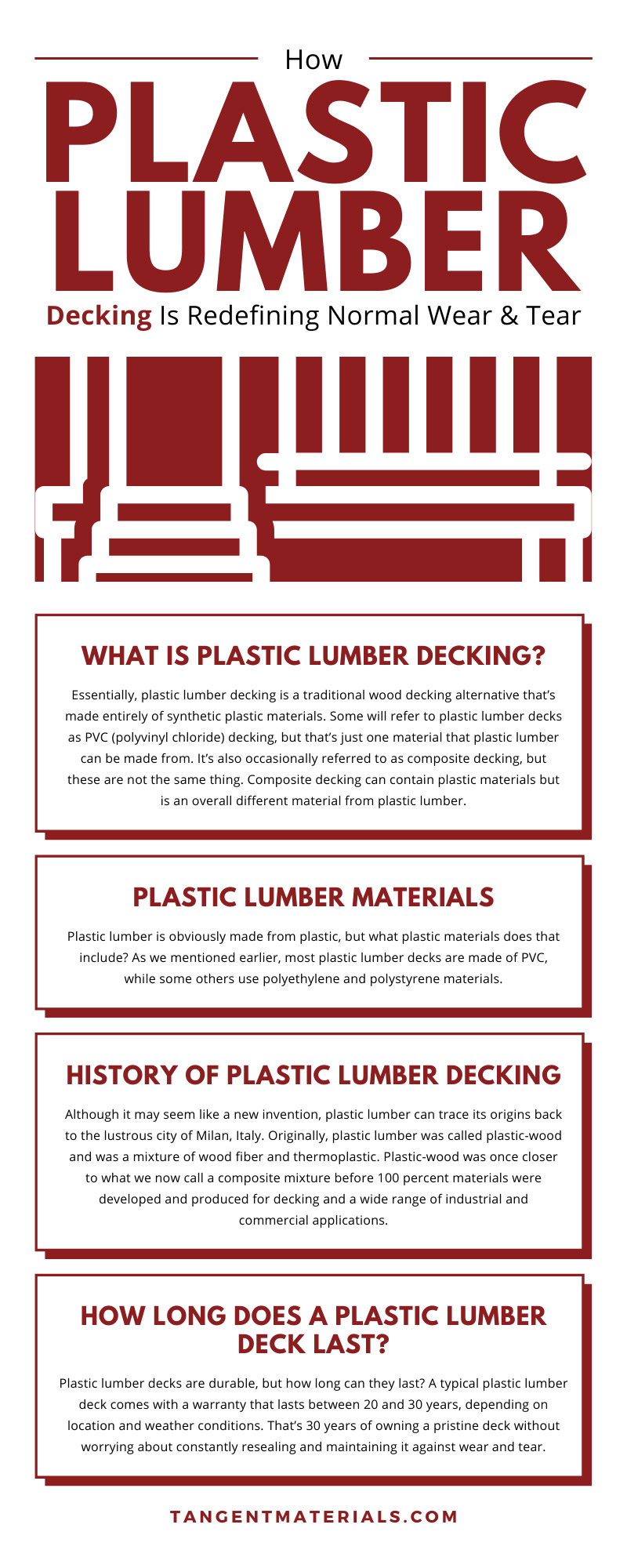

What Is Plastic Lumber Decking?

Before we can get into the nitty-gritty details and benefits of plastic lumber, we’ll explain what a plastic lumber deck is. Essentially, plastic lumber decking is a traditional wood decking alternative that’s made entirely of synthetic plastic materials.

Some will refer to plastic lumber decks as PVC (polyvinyl chloride) decking, but that’s just one material that plastic lumber can be made from. It’s also occasionally referred to as composite decking, but these are not the same thing. Composite decking can contain plastic materials but is an overall different material from plastic lumber.

Plastic Lumber Materials

Plastic lumber is obviously made from plastic, but what plastic materials does that include? As we mentioned earlier, most plastic lumber decks are made of PVC, while some others use polyethylene and polystyrene materials.

Each material brings some distinct benefits to the table, but each offers the typical advantages of plastic decks. Plastic lumber, regardless of the material, will be durable, low-maintenance, and present numerous customization options, from thickness to color.

History of Plastic Lumber Decking

Where did plastic lumber come from? How long has it been around? Although it may seem like a new invention, plastic lumber can trace its origins back to the lustrous city of Milan, Italy.

Originally, plastic lumber was called plastic-wood and was a mixture of wood fiber and thermoplastic. Plastic-wood was once closer to what we now call a composite mixture before 100 percent materials were developed and produced for decking and a wide range of industrial and commercial applications.

The Durability of Plastic Lumber vs. Wood Decks

Perhaps the most significant contribution that plastic lumber decking has made to the industry is in how it’s redefining normal wear and tear. Wood decks have a beautiful aesthetic and look, but there’s no doubt they require a lot of maintenance.

Wood decks must be chemically treated before they can be installed to protect them from weather conditions, rot, and insect infestation. And a wooden deck requires strict maintenance and cleaning throughout its life to reseal and protect the wood from these conditions and threats to its structural integrity.

A plastic lumber deck, on the other hand, is not made of organic materials. Thanks to its plastic materials, a plastic lumber deck won’t rot or produce mildew. Plus, because it doesn’t contain organic materials, insects like termites won’t infiltrate it and gnaw away at the structure.

How Long Does a Plastic Lumber Deck Last?

Plastic lumber decks are durable, but how long can they last? A typical plastic lumber deck comes with a warranty that lasts between 20 and 30 years, depending on location and weather conditions. That’s 30 years of owning a pristine deck without worrying about constantly resealing and maintaining it against wear and tear.

Meanwhile, a standard wooden deck will only last about half that time. Plus, that time frame involves hours of diligently maintaining and repairing a wooden deck against the weather, rot, mildew, and insect infestations.

Other Benefits of Plastic Lumber Decks

Plastic lumber decks are durable and long-lasting, but those aren’t the only benefits. Plastic lumber offers simple and varied customization and is safe, low-maintenance, and environmentally friendly.

Customization

One of the prime benefits of plastic lumber is that manufacturers can customize the material to the exact specifications they need. Manufacturers can produce plastic lumber decks in any thickness, dimension, shape, or color that the buyer requires.

We all know how wood can be cut and shaped, but there are obvious limitations to morphing wooden planks and boards. Plastic lumber decking gives owners more opportunities and fewer limitations than typical wood material.

Safety

One of the consequences of plastic lumber being more durable and long-lasting is that it’s also safer. As wood ages and goes through seasons of wear and tear, it cracks, chips, and splinters.

We’ve probably experienced getting a splinter from an old wood deck, but that’s not an issue with plastic lumber. It’s not indestructible, but plastic lumber is much less likely to chip and splinter than its wood counterpart. Plus, since insects don’t bother with plastic materials, there are fewer pests around bugging and biting nearby occupants.

Low-Maintenance

Even though a plastic lumber deck will last longer than wooden materials, it does so despite requiring less maintenance. A wooden deck requires a lot of effort to keep it from fading and rotting, but plastic lumber doesn’t deteriorate like typical lumber.

Synthetic materials don’t age like organic materials, and plastic lumber doesn’t need chemical treatments and sealants to ensure protection against water and infestation. Not only does this make life easier for homeowners, but it saves money on long-term maintenance and repair costs compared to wood decks.

Environmentally Friendly

Another massive difference between plastic and organic lumber is that it’s much more environmentally friendly because it preserves organic materials, doesn’t require chemical treatments, and is 100 percent recyclable.

Recycled Materials > Organic Materials

Trees may be a renewable resource, but deforestation is a major environmental problem worldwide. Instead of cutting down trees to create the lumber needed for a wood deck, plastic lumber preserves trees and our forests.

If deforestation and preserving organic materials is a significant issue to you, making the switch to plastic lumber is the more environmentally friendly option.

Fewer Chemicals

Lumber requires many chemical treatments and sealants to protect it from mildew and insects. These chemicals are typically safe, but they can be harmful to the environment. These chemicals can eventually leech off the wood and infect the environment. This is a particular concern when building marine decking, as these chemicals can leech into waterways.

Plastic marine decking doesn’t have this problem because synthetic materials don’t require sealants and chemical treatments for protection.

100 Percent Recyclable

At the end of a plastic lumber deck’s life cycle, every part of it can be recycled and used again. Since plastic lumber is made of 100 percent materials, it can be entirely recycled for later use to create other products, including pallets, fencing, furniture, and more.

Wood decks aren’t as recyclable, especially after they’ve been through decades of wear and tear. If you care about sustainability and efficient use of resources, a plastic lumber deck is the clear way to go.