Everything To Know About High-Density Polyethylene Sheets

There are many green solutions for traditional materials today. While consumers shift towards sustainable lifestyles, many companies, municipalities, and industries are doing the same. One material that has made its mark as a green alternative to wood is high-density polyethylene plastic sheets. It’s great for many structural, commercial, or marine applications without the existing issues found in traditional wood, like rot, cracks, or mold. Here’s everything to know about high-density polyethylene (HDPE) sheets to help you with your project. No matter what, HDPE plastic lumber is a strong, durable, environmentally friendly building material that will last for years to come.

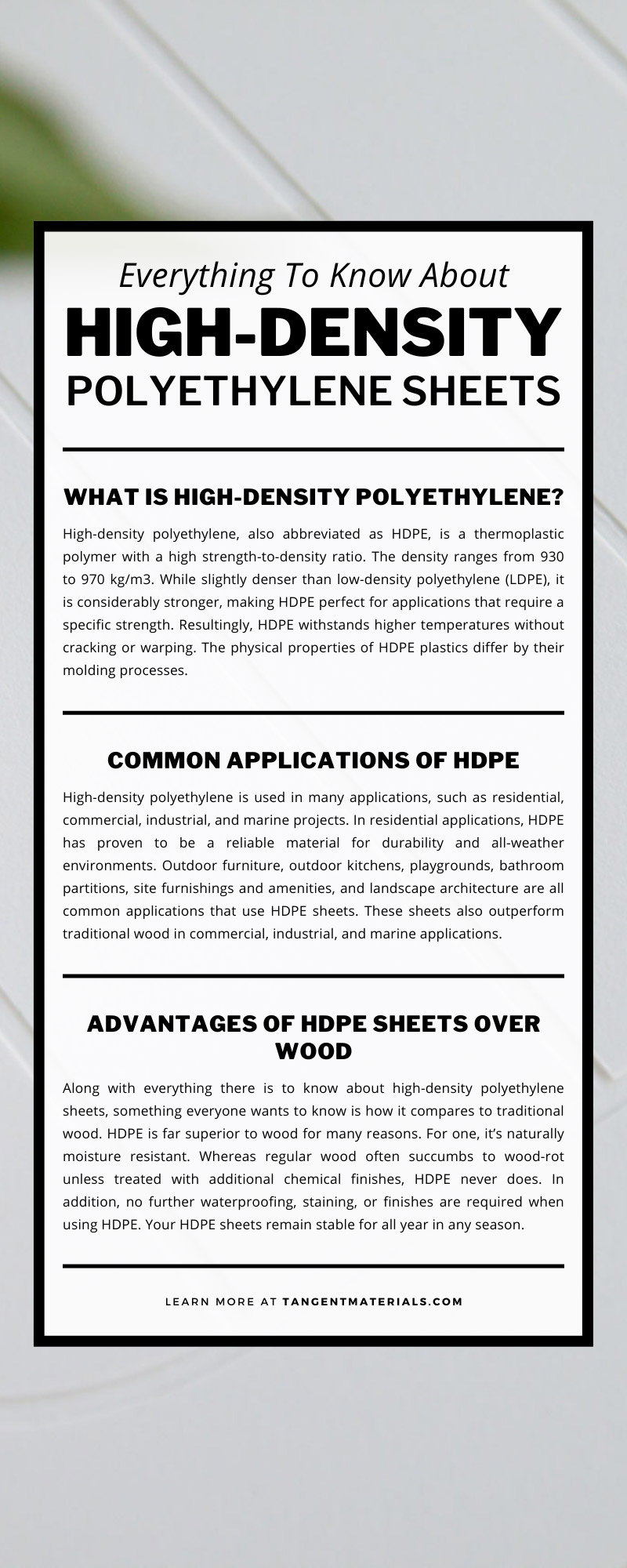

What Is High-Density Polyethylene?

High-density polyethylene, also abbreviated as HDPE, is a thermoplastic polymer with a high strength-to-density ratio. The density ranges from 930 to 970 kg/m3. While slightly denser than low-density polyethylene (LDPE), it is considerably stronger, making HDPE perfect for applications that require a specific strength. Resultingly, HDPE withstands higher temperatures without cracking or warping. The physical properties of HDPE plastics differ by their molding processes. Many times, HDPE is configured based on certain specifications. Since it can be cut, molded, and altered similarly to wood or timber, HDPE sheets offer many other advantages given their plastic composition. It’s naturally moisture-resistant, pest-resistant, and does not require further chemical treatments or finishes in outdoor applications. These advantages have made HDPE a reliable, durable, and resilient material for residential, commercial, industrial, and marine-grade applications. HDPE does have a melting point of about 267 degrees, so keep this in mind if using HDPE near extremely high temperatures.

Common Applications of HDPE

High-density polyethylene is used in many applications, such as residential, commercial, industrial, and marine projects. In residential applications, HDPE has proven to be a reliable material for durability and all-weather environments. Outdoor furniture, outdoor kitchens, playgrounds, bathroom partitions, site furnishings and amenities, and landscape architecture are all common applications that use HDPE sheets. These sheets also outperform traditional wood in commercial, industrial, and marine applications. For example, HDPE is an efficient building material for marine decking. With the same aesthetics as natural wood, HDPE marine decking requires less maintenance or waterproofing, yet still delivers strong resilience to environmental conditions. The wood grain finish further ensures a natural wood aesthetic with slip-proof resistance. Commercial docks and marinas benefit from HDPE sheets given these advantages.

Even in other applications, high-density polyethylene stands out above other materials. Commonly, HDPE is used for commercial and urban site amenities, park and recreation site amenities, or golf courses. It can also be used for custom commercial solutions, hospitality, and outdoor living. Therefore, the versatility of high-density polyethylene materials offers greater style and performance choices for commercial properties that want to enhance their current aesthetics or functionality.

Advantages of HDPE Sheets Over Wood

Along with everything there is to know about high-density polyethylene sheets, something everyone wants to know is how it compares to traditional wood. HDPE is far superior to wood for many reasons. For one, it’s naturally moisture resistant. Whereas regular wood often succumbs to wood-rot unless treated with additional chemical finishes, HDPE never does. In addition, no further waterproofing, staining, or finishes are required when using HDPE. Your HDPE sheets remain stable for all year in any season.

As previously mentioned, HDPE is also moldable to any specific application. High-density polyethylene sheets cut, mold, and shape as well as wood. The plastic composition offers unmatched malleability not commonly found in other materials.

Unlike wood, HDPE is also naturally corrosive-resistant. HDPE sheets resist mold, mildew, and insect infestations. That way, you never face health or safety issues with HDPE in marine or outdoor applications as you might with traditional wood.

Another advantage to consider is that HDPE can withstand natural and artificial chemicals. It’s impervious to solvents, acids, detergents, and cleaning fluids. In fact, because it’s also low maintenance, cleaning your HDPE sheets is easier than ever. Simply use soap and water.

You save more time and money from the low-maintenance HDPE solution than consistently repairing or treating traditional wood. More so, high-density polyethylene retains a wood-like aesthetic with a slip-proof surface. With many colors to choose from, such as red, white, black, gray, or royal blue, you’ll find the right HDPE material for your outdoor furniture or site amenities without feeling like you’re using cheap plastic.

Still, perhaps the best part of using high-density polyethylene is that it’s more sustainable. HDPE sheets are made of recycled plastics from bottles, milk jugs, plastic bags, and bottle crates. HDPE has even been considered more environmentally friendly and safer for consumers than other recycled goods, like PVC, BPA, glass, metal, and cardboard. The wide use of HDPE plastic wood over traditional wood saves natural ecosystems from deforestation and other associated environmental effects from those industries. If your HDPE is broken or needs to be replaced, you can either recycle it or send it back to the manufacturer, making HDPE a reusable material for years to come.

Possible Considerations

With all that said, there are some possible considerations to be aware of when using HDPE sheets. The main consideration is its melting point. When used in significantly hot climates or industrial applications, HDPE can melt or warp under stress from extreme temperatures. Another consideration is that HDPE is not biodegradable or compostable. Still, it is an efficient sustainable material that can complement a compost site as a secure barrier and protect against mold or insects.

When looking for a superior alternative to wood, Tangent Materials has the answer. We offer a wide variety of sizes, colors, and product lines so you can find the right structural material for the job. Our high-density polyethylene sheets are the perfect solution for your residential or commercial application. They’re durable, color stable, customizable, and easy to clean. Perfect for all-weather seasons, HDPE sheets come designed unparallel to traditional lumber. These sheets also go through vigorous product quality and consistency to ensure they’re up to our standards. If you have any questions about our products, please don’t hesitate to call. We’re here to answer your questions or concerns to help with your order as fast as possible.