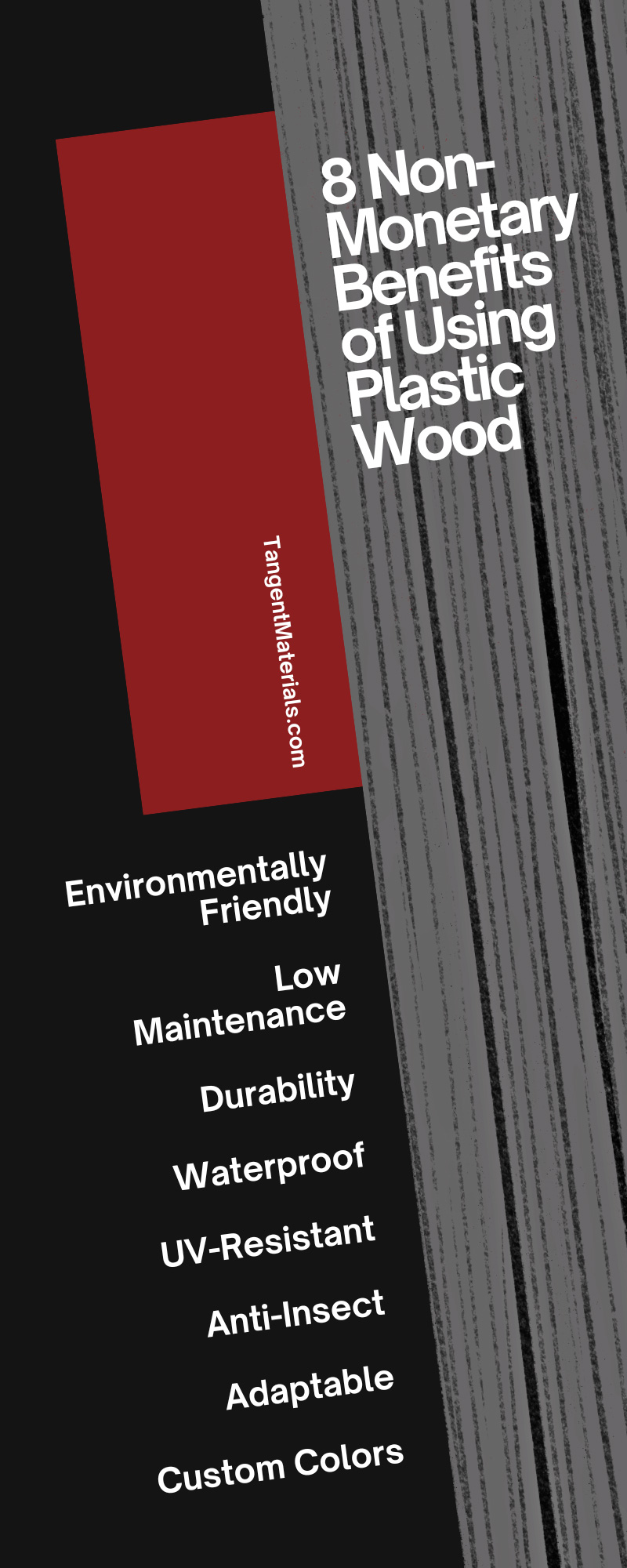

8 Benefits of Using Plastic Wood

Plastic lumber offers users many benefits besides saving money and delivering better value. In our guide, you’ll find all the non-monetary benefits of using plastic wood over natural lumber, from its usefulness to the environment to its custom colors.

Popular Plastic Wood Materials

Before we get into the non-monetary benefits of using plastic wood, we’ll briefly describe and analyze the most popular plastic wood materials. You will likely see these three plastic wood materials when shopping for plastic lumber for commercial, residential, or structural applications.

Polyvinyl Chloride (PVC)

PVC is a popular plastic wood material mostly used in residential settings. Like all plastic woods, it won’t rot or split from moisture and can come in any custom colors, which is why it’s very popular for exterior home trims.

If you’ve seen a home built in the last 30 years, you’ve witnessed PVC exterior trim on the outside. Other common applications for PVC include:

- Window frame trim

- Door frame trim

- Drainage pipe

- Flooring

- Roofing

High-Density Polyethylene (HDPE)

HDPE is a very strong and durable plastic wood material used in various commercial and structural applications. HDPE is known for its light weight and strength, making it a popular substitution for organic wood in many settings.

Due to its ability to withstand moisture and natural elements, HDPE is commonly used in marine and outdoor settings. Typical applications for HDPE materials include:

- Retaining walls

- Boating docks

- Outdoor furniture

- Boardwalks

- Retaining walls

Wood Plastic Composite

Composite wood is a little different than the other materials, but it is what it sounds like—a composition of two different materials. Composite wood combines organic wood with recycled plastic to create one lumber material.

Interesting Fact: Composite wood uses organic wood but can be created with wood waste materials (chipped trees, bark, sawdust, tree limbs) and smaller trees, so it’s still environmentally friendly.

The benefit of composite wood is that it offers the strength of both standard wood and plastic and more closely mimics the aesthetics of natural lumber. Composite wood is utilized in many applications, but its most popular use is outdoor decking. Other uses for composite lumber include:

- Fences

- Benches

- Railings

- Window frames

- Landscaping work

Environmentally Friendly

Normally, you wouldn’t consider plastic the most environmentally friendly choice of materials, but in this case, it’s more sustainable and greener than other lumber and building materials. Plastic wood manufacturers create synthetic lumber out of high-quality recycled plastics from things like milk jugs.

By using these recycled milk jugs and other plastics, plastic lumber helps clear out our landfills and oceans of harmful plastics. Plus, unlike organic lumber, no trees must be chopped down, which means more intact forests and ecosystems. If protecting the environment is a major concern for you, there’s no doubt that plastic lumber is the better choice.

Low Maintenance

Whether for residential construction or furniture manufacturing, real wood requires chemical treatments and stains to protect it during its lifespan. And organic lumber needs to be cleaned and maintained constantly with more treatments and high-pressure washing to retain its look and structural integrity.

Plastic wood, on the other hand, requires much less maintenance—no power washing, no waterproof staining, and no chemical treatments. Plastic lumber is easy to clean with minimal fuss, and owners never have to worry about rot, termites, warping, or any other problems real wood brings.

Durability

Even though synthetic lumber requires much less maintenance and repairs, it still lasts much longer than organic wood and is structurally more durable. Plastic lumber doesn’t split, crack, swell, or shrink like organic wood after years of use and exposure to the elements.

Plastic lumber is created with tougher materials and stronger protective coatings, allowing it to withstand damage and exposure for much longer. Plastic wood is the best of both worlds, as it’s longer lasting and requires less maintenance for owners.

Waterproof

The major advantage plastic materials hold over organic wood is that plastic lumber is waterproof. Synthetic materials don’t absorb moisture like natural wood, so it doesn’t swell or become a breeding ground for rot.

Whether rain, saltwater, or freshwater, plastic lumber remains 100 percent waterproof without chemical treatments or coatings. If you need materials for marine and water applications, there’s no doubt that plastic wood would be a much easier and more reliable option than natural wood.

UV-Resistant

Another major problem with natural wood is if it’s exposed to the sun every day, it can experience discoloration and fade from the UV rays. After months or years outside, natural lumber has to be repainted, stained, and treated to retain its vibrant colors and look.

Plastic lumber, on the other hand, doesn’t have this problem because it’s sealed with a powerful coating like acrylic polymer. Along with this protection, plastic isn’t susceptible to UV exposure like natural materials and won’t lose its color and luster. Plastic wood could spend years in the sun and the surf and look the same as the day you installed it!

Anti-Insect

Another major source of problems for natural wood is termites and other pest infestations. An infestation can destroy the structural integrity of wood in no time, causing unsafe conditions and necessitating extensive repairs.

But there’s no worry of termites infesting plastic lumber. For one, insects aren’t interested in synthetic lumber materials because they can’t ingest plastic. With plastic wood, termites won’t bother, and you don’t have to worry about them!

Adaptable

Despite the strength and rigidity of plastic wood, it’s still as adaptable and useful in various applications as regular wood. Like natural wood, plastic lumber can be adapted and tailored to the exact specifications.

Cut and mold the plastic lumber the same way you would with natural wood. Saw it, nail it, and transform it any way you want—plastic wood is just as adaptable as organic lumber.

Custom Colors

An added perk of synthetic materials is that they’re available in various colors, so you can get exactly what you’re looking for. Plastic manufacturers can create plastic lumber in practically any color you desire, so there’s no need to paint the lumber.

It saves you the hassle of having to paint and repaint the wood every few years and opens up more design possibilities. Plastic lumber can also come with a wood grain finish to get the look of natural lumber with all the practical benefits of plastic—a win-win!

We hope you understand more about plastic lumber’s benefits and advantages to residential, commercial, and structural applications. If you have more questions or are interested in purchasing plastic wood, contact the experts at Tangent Materials!