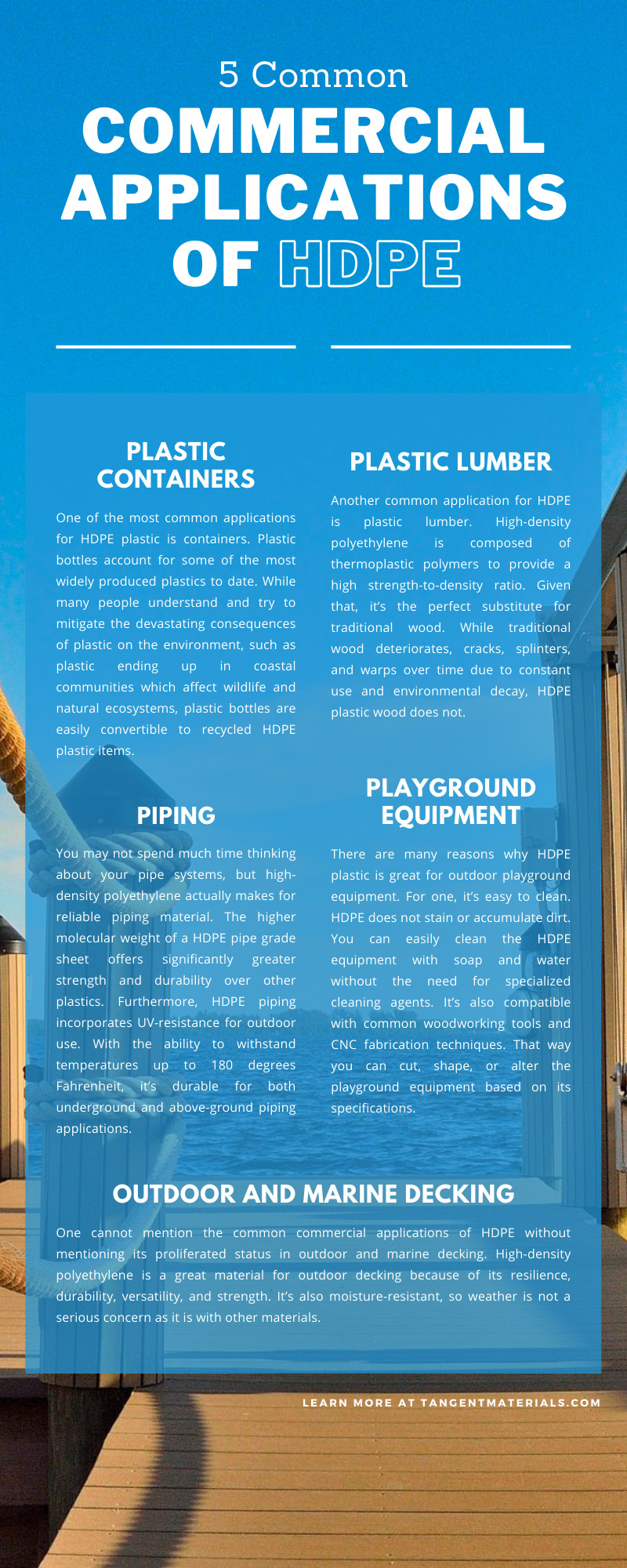

5 Common Commercial Applications of HDPE

High-density polyethylene (HDPE) is a rising thermoplastic resin material used for a wide variety of applications. Due to its high strength-to-density ratio, it’s proven reliable in residential, commercial, and industrial sectors. From individual water bottles to industrial piping, HDPE proves its worth. For example, here are five common commercial applications of HDPE you should know about to see the various ways it stands out against traditional materials.

Plastic Containers

One of the most common applications for HDPE plastic is containers. Plastic bottles account for some of the most widely produced plastics to date. While many people understand and try to mitigate the devastating consequences of plastic on the environment, such as plastic ending up in coastal communities which affect wildlife and natural ecosystems, plastic bottles are easily convertible to recycled HDPE plastic items. One of which is other bottles therefore truly making use of repurposing and reducing overall consumption.

Aside from durable water bottles, HDPE is also perfect for food and beverage containers. This way food and beverage contaminants don’t leak into the plastic. After a simple cleaning, the plastic is ready for recycling and repurposed into other goods. With that in mind, HDPE is perfect for industrial containers too, like chemical containers, cleaning fluids, agricultural chemical agents, and other industrial fluids due to the high-resistance and strength of the plastic polymers. HDPE polymers withstand chemical agents without deterioration or corrosion, making them the perfect solution for industrial and residential items.

Plastic Lumber

Another common application for HDPE is plastic lumber. High-density polyethylene is composed of thermoplastic polymers to provide a high strength-to-density ratio. Given that, it’s the perfect substitute for traditional wood. While traditional wood deteriorates, cracks, splinters, and warps over time due to constant use and environmental decay, HDPE plastic wood does not. HDPE plastic lumber only breaks or loses shape in extreme climates, but for traditional applications, like residential decking or marine boardwalks, this isn’t a common concern. Recycled plastic lumber uses recycled HDPE plastic for its strength, dexterity, and resilience for structural applications. Sometimes even fiberglass and other reinforcement materials provide additional support for heavy-duty projects, like coastal retention.

Plastic lumber is an optimal commercial material because it also doesn’t succumb to pest infestations or moisture. Whereas traditional wood often faces termite infestations and mold—both of which cause the material to weaken—HDPE plastic lumber never does. Not to mention, HDPE plastic lumber comes ready in various dimensions and specifications. Even if you use HDPE plastic boards, you can cut, shape, and finish plastic lumber in the same ways as traditional wood. There’s no application, large or small, that plastic wood cannot offer a reliable alternative for.

Piping

You may not spend much time thinking about your pipe systems, but high-density polyethylene actually makes for reliable piping material. The higher molecular weight of a HDPE pipe grade sheet offers significantly greater strength and durability over other plastics. Furthermore, HDPE piping incorporates UV-resistance for outdoor use. With the ability to withstand temperatures up to 180 degrees Fahrenheit, it’s durable for both underground and above-ground piping applications. Plumbers who use chemical agents don’t need to worry about harmful interactions with HDPE piping sheets, either. HDPE withstands chemical irritants without issue.

Whereas metal pipes leak heavy metals and other residue into the water supply, HDPE plastic piping never leaches harmful contaminants. The strong polymer ratio within HDPE is perfect for residential, commercial, and industrial piping. For instance, flexible HDPE pipes ensure potable water for households. More so, HDPE pipes also protect against steel corrosion and are the optimal solution for fluids, slurry, and gas purposes. While previously thought to last only 50 years, pipe systems can reasonably last up to 100 years until major repairs are needed.

Outdoor and Marine Decking

One cannot mention the common commercial applications of HDPE without mentioning its proliferated status in outdoor and marine decking. As previously mentioned, high-density polyethylene is a great material for outdoor decking because of its resilience, durability, versatility, and strength. It’s also moisture-resistant, so weather is not a serious concern as it is with other materials. HDPE plastic is a low maintenance material. You save more money opting for HDPE plastic than you would with other materials given the little maintenance required. Feel free to add furniture onto your outdoor deck since HDPE plastic’s strength and resilience ensure no damage is done.

Additionally, HDPE plastic is perfect for marine decking and boardwalks. The high moisture-resistance protects against water damage as well as mold and insect infestations. You may also opt for HDPE coastal barriers, residential boat docks, marinas, piers, and light commercial applications for waterfront properties and structures. The aesthetics don’t falter, either. The wood-like texture and finish ensure a beautiful marine dock board with additional durability and low maintenance.

Playground Equipment

There are many reasons why HDPE plastic is great for outdoor playground equipment. For one, it’s easy to clean. HDPE does not stain or accumulate dirt. You can easily clean the HDPE equipment with soap and water without the need for specialized cleaning agents. It’s also compatible with common woodworking tools and CNC fabrication techniques. That way you can cut, shape, or alter the playground equipment based on its specifications. Given the low maintenance of the material, there is no additional painting, staining, or waterproofing required. Bugs won’t penetrate the surface, making it a safe environment for children to play. With a significantly greater impact resistance than wood, high-density polyethylene is the perfect material for any public or school playground where children run, jump, and play, without losing its quality from consistent use.

With these commercial applications in mind, be sure to check out Tangent Materials for plastic lumber. We sell strong, durable, aesthetic HDPE plastic lumber perfect for residential, commercial, marine, and industrial applications. We deliver products you can depend on that are unrivaled in performance and quality compared to other materials. We pride ourselves on innovation, which is why our products are made from recycled HDPE plastic to offer a greener solution for any application. Large or small, there’s no project our plastic lumber cannot handle. You’ll see the difference in aesthetics, toughness, and longevity. Don’t wait! Call now to learn more about our HDPE plastic lumber and which products are best for your residential, commercial, industrial, or marine application.